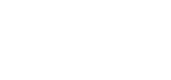

Industry-first 1m road planer with performance tracking

Jet Plant continues to set the standard for sustainability in the road planing industry with the groundbreaking launch of the W100Fi planer.

An industry-first Wirtgen 1m tracked machine that is 25% more fuel efficient and fitted with Wirtgen performance trackers. Until now, performance trackers could only be found on two-metre track road planing machines.

The new W100Fi tracked planers offer 25% better fuel efficiency using a new John Deere engine, but you won’t find any drop in power or performance.

Jet Plant is able to fuel these machines using Hydro Treated Vegetable Oil (HVO), creating the possibility for a 90% COշ reduction on every job, helping customers put sustainability at the top of their agenda.

What’s more, Jet Plant will offset the higher cost of HVO fuel against the improved fuel efficiency of the new engines, meaning that sustainable road planing comes at no extra cost to customers.

On-board telematics allow Jet Plant to monitor performance on behalf of our customers. We can provide data-led feedback on fuel usage, idling time, tonnage of material, water usage and the exact area and depth of planing.

This smart solution enables greater optimisation of machinery, leading to better on-site management; giving customers the information they need to make steps to reduce their carbon footprint.

Working in partnership with our customers, Jet Plant firmly believes that a shared commitment to sustainability can bring about real change.

1M Tracked Planer Key Specs

- Milling Width:

- 1,000 mm

- Engine Output:

- 260 kw

- Milling Depth:

- 0 - 330 mm

- Operating Weight:

- 20,000 kg

- Milling Drum Drive:

- Mechanical

- Number of Tracks:

- 4 Crawler Tracks

- Travel Drive System:

- Hydraulic/all-crawlers